Product description

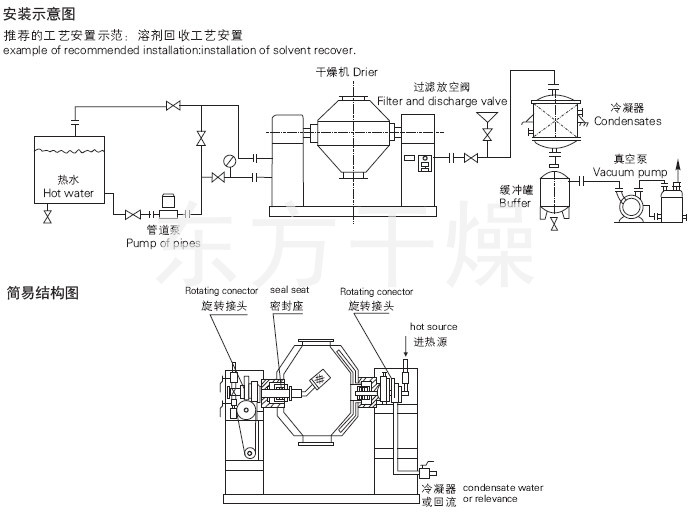

SZG double cone vacuum dryer drying apparatus is a new generation factory in domestic similar products combine technology developed, using a double cone vacuum belt - chain two elastic coupling manner, thus equipment running smoothly. Specially designed technology, fully reflects the good two concentric shafts, heat medium and vacuum systems are using a reliable mechanical seal or rotary joint US technology. On this basis, we have developed SZG-A It can be variable speed, but also for climate control.

As a professional drying equipment factory, plant products from the high temperature thermal oil as medium quality, low temperature steam and hot water readily available. Drying the adhesive material, the factory will be designed especially for you "copy board" mechanism or set balls in the tank.

Working principle

◎Sealed jacket pass into the thermal energy source (such as hot water, low pressure steam or thermal oil), heat is passed through the inner shell dried material.

◎Under driving of power, the tank is rotated slowly and continuously mixing tank material, so as to achieve the purpose of drying strengthen.

◎Material in a vacuum, vapor pressure drops to a moisture (solvent) saturated material surface and evaporates, and is discharged by the vacuum pump timely recovery. Material inner moisture (solvent) continuously to the surface infiltration, evaporation, discharge three ongoing process, the purpose of drying the material in a very short period of time.

Features

◎Oil heating. Automatic climate control. Biochemical products can be dried.

◎And mineral raw materials, the temperature can be between 20 ~ 160oC.

◎High thermal efficiency, improve oven than 2 times.

◎Indirect heating. The material will not be contaminated, in line with "GMP" requirements. Equipment maintenance is simple, easy to clean.

◎Recommended placement process demonstration solvent recovery process resettlement.

Adapt materials

Applicable concentrated chemical, pharmaceutical, food and other industries powder, granular and fibers, mixing, drying and the need for low-temperature drying of materials (such as biological products, etc.). More suitable for oxidation, volatile, drying heat-sensitive, strong stimulation, toxic and not permitted to destroy the crystal material.

Technical Specifications

|

Specification Name |

100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| 罐內(nèi)容積 | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

| Loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| Heating area (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

| Rotating speed (rpm) | 4 - 6 | |||||||||

| Motor Power (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

| It covers an area of length × width(mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

| Rotating height(mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

|

Tank design pressure (MPa) |

-0.1-0.15 | |||||||||

| Jacket design pressure (MPa) | ≤0.3 | |||||||||

| Operating temperature (oC) | Tank≤85 Jacket≤140 | |||||||||

| With a condenser, the vacuum pump, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| Type, power | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

| When not in condenser vacuum pump , | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| Type, power | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| Weight(kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

NOTE: The volume change before and after drying a lot of material, it may be appropriate to increase the charge coefficient or reduced.