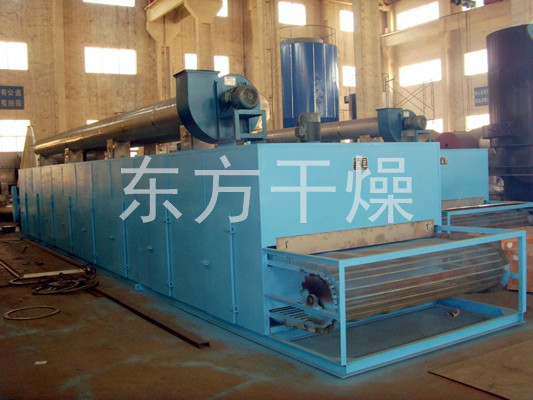

Products description

This machine is a continuous cross-flow drying equipment for better ventilation sheet, strip, dry granular materials, for dehydrated vegetables, Chinese Herbal Medicine and other types of high moisture content and high temperature materials are particularly suitable allowed ; the series dryer has a drying speed, high evaporation strength, good product quality advantages of the dehydrated cake-like paste materials, to be made after granulation or rod can also be dried.

Working principle

The material on the belt from the feeder evenly over the mesh belt generally adopts 12-60 mesh stainless steel mesh, drag from the gear in the dryer moving. Drying machine consists of several units, each unit independent hot air circulation, humidity and the fan portion of the tail by specialized discharged from the exhaust gas control valve, the heat from bottom to top or from top to bottom through the material covered belt complete with heat mass transfer process, material moisture away. Belt moves slowly, running speed can be freely adjusted according to the material temperature, the finished product after drying receive continuous fall feeder. Upper and lower circulation unit can be flexibly equipped according to user needs, according to the number of units you may also need to select.

Features

◎ can adjust the amount of air, heating temperature, residence time and feed rate to achieve the best drying results.

◎ device configuration flexibility, you can use the network with a flushing system and material cooling system.

◎ most of the air recycling, highly energy saving.

◎ unique air distribution means more even distribution of hot air, to ensure product quality and consistency.

◎ heat source can be steam, oil, electricity or coal-fired (oil) stove supporting.

Adapt materials

Dehydrated vegetables, grain feed, monosodium glutamate, coconut, organic pigments, synthetic rubber, acrylic fiber, medicines, herbs, wooden products, plastic products, electronic devices without aging and curing.

Technical Specifications

| Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

| Number of units | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Bandwidth(m) | 1.2 | 1.6 | 2 | |||||

| Long drying section(m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Shop material thickness(mm) | 10-80 | |||||||

| Operating temperature(oC) | 50-140 | |||||||

| Steam pressure(MPa) | 0.2-0.8 | |||||||

| Steam consumption (kg/h) | 120-300 | 150-375 | 150-400 | 180-500 | 180-500 | 225-600 | 450-1200 | |

| Drying time(h) | 0.2-1.2 | 1.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.5-3 | |

| Dry strength kg water/h | 60-160 | 80-200 | 85-220 | 100-260 | 100-260 | 120-300 | 240-600 | |

| Total power (kw) | 11.4 | 13.6 | 14.6 | 18.7 | 19.7 | 24.5 | 51 | |

| long(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 | |

| Dimensions | width(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| high(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Total weight kg | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |